Wison Engineering

Wison New Energies

Wison Group

Wison Engineering

Wison New Energies

Petrochemical

Wison Engineering

Address : No. 633, Zhang Jiang, Pudong New Area, Shanghai, China

Phone : +86-21-20306000

Email : eng@wison.com

Wison Engineering started its business by providing engineering services to ethylene complexes and its downstream production units, then has gradually expanded upstream. Wison now has the capacity to provide high quality engineering solutions for worldwide clients in multiple petrochemical sectors.

Applications

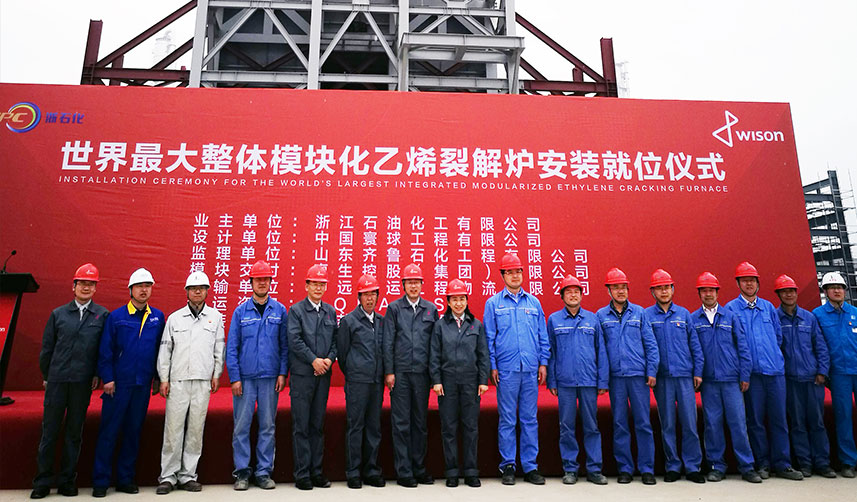

Zhejiang Petrochemical – Cracking Furnaces of 1,400 KTA Ethylene Plant

This cracking furnace weighing 3689.6 tons with a height of 53.31 meters has an annual production capacity of 200,000 tons of ethylene. It is the world’s largest single-unit liquid cracking furnace completed with modular construction and transportation, and it is the largest single production capacity ethylene cracking furnace in China. Wison Engineering completed the modular design, construction and final assembly of the first cracking furnace in just 5 months, thus, laying the foundation for Zhejiang Petrochemical to put it into production as scheduled which was highly recognized by the owners.

The overall modular construction of the cracking furnace is a manifestation of the company's comprehensive strength. The synergy effect of EPC was clear, from project planning, program selection, material management, long-lead procurement, construction technology, professional offshore cooperation, transportation coordination, etc. Scientific organization, careful planning, and integration of resources by all parties controls the relationship between cost, quality, and progress to ensure the safe and reliable implementation of the project.

PetroChina Fushun Petrochemical – 800 KTA Ethylene Plant

The project commenced on 30 April 2009 with pre-commissioning completed on 20 July 2012. Wison is providing EM+PC services for the project.

PetroChina Dushanzi Petrochemical – 600 KTA FDPE Plant

The project commenced on 28 March 2007 with pre-commissioning completed on 15 June 2009, cumulatively achieving 3 million manhours without a lost time incident.

PetroChina Fushun Petrochemical – 100 KTA SSBR & 80 KTA SBS Rubber Project

The plant was built to produce 23 different products including SSBR/ LCBR/ SB/SBS. Specifically, the plant has a solution styrene butadiene rubber (SSBR) capacity of 100 KTA and the styrene butadiene styrene (SBS) rubber capacity of 80 KTA, making it the largest rubber plant in the world. Civil work of the project began on 8 October 2006 and the plant was commissioned on 15 June 2009, cumulatively achieving 5 million manhours without a lost time incident.

Corporate Profile

Wison. Ignite innovation.

Mission, Vision and Values

Wison Center

Milestones

News

Media Report

Industry

Services

Why Us

About Us

About Us

Products & Services

Project Showcase

Yard Facilities

Sustainable Development

Culture

Public welfare

Career Path

Recruitment

Work at Wison